In the spotlight: Research project Everlong

As stressed in the latest report by the Intergovernmental Panel on Climate Change (IPCC), we need ‘immediate and deep emissions reductions across all sectors’ to fight climate change. That’s why we’re proud to be a partner in the ambitious EverLoNG project. This research project will enable us to drastically reduce CO2 emissions from ships.

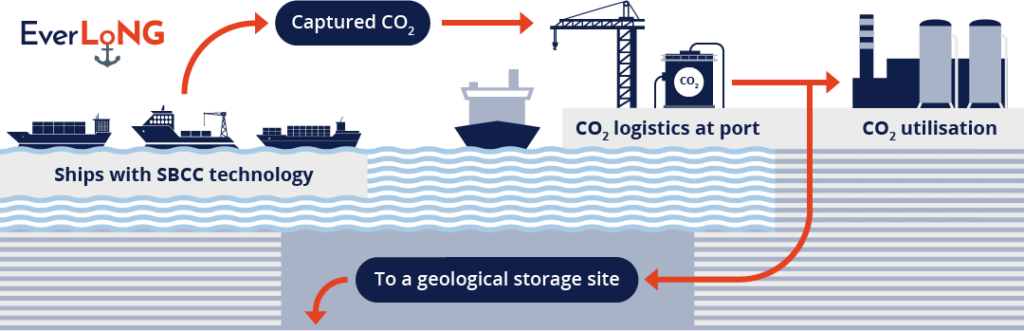

As the whole world looked towards alternative fuels as the solution for decarbonizing the maritime industry, our colleague Joan van den Akker explored a different approach. What if we could use carbon capture technologies onboard? Joan researched this topic in his master thesis back at TU Delft in 2017. He looked at the feasibility of placing carbon capture technology on ships, capturing the CO2 from the ship’s exhaust gases and storing it onboard. The CO2 can then be unloaded when the ship reaches a port, and can be used as a resource by the chemical industry. This would revolutionise the way we approach the decarbonization of the maritime industry.

Ship-based Carbon Capture

Adding (post-combustion) carbon capture technology to existing diesel or LNG propulsion vessels is a promising solution to reduce our carbon footprint in the short term. DNV, the leading expert in assurance and risk management in the maritime industry, already theoretically proved the feasibility of ship-based carbon capture (SBCC) in 2013. TNO, the Netherlands Organisation for applied scientific research, has been researching since 2017 how to adapt existing land-based carbon capture technologies to use them on ships. Our researchers have contributed to several research projects on SBCC, like Co2ast, DerisCO2 and LNG-Zero. In this EverLoNG research project we will contribute to the optimisation process of the technology and consider how best to integrate it into existing ship and port infrastructure.

The EverLoNG Project

The EverLoNG project, led by TNO, will demonstrate Ship-Based Carbon Capture on board two LNG-fuelled ships, owned and operated by project partners TotalEnergies and Heerema Marine Contractors. With its results, the project aims to bring the technology closer to market readiness.

The program consists of six work packages, each with their own perspective on the research question: how can we optimise the technology and integrate it into the existing ship and port infrastructure? As a research partner, we contribute to all six work packages, but we are taking the lead in work package 3.

Six work packages:

- WP1. Demonstrating ship-based carbon capture

EverLoNG’s prototype will be designed, engineered, built and operated within WP1. This small-scale prototype unit, which can capture ten tonnes of CO2 on board, will first be installed on board TotalEnergies’ LNG carrier. During a 3000-hour test campaign a life-cycle analysis (part of WP4) will be performed, providing data on environmental emissions and the impact the motion of the ship has on capture rates, capture solvent behaviour and degradation. The prototype unitwill be moved on board Heerema’s Sleipnir for a second campaign of around 500 hours of CO2-capture operations to compare the system performance on both vessels and provide further insights. - WP2. Ship-based carbon capture in the full CCUS chain

In the second WP we assume a more holistic view of SBCC as part of an international carbon capture and utilisation (CCUS) network. It will concern the quality requirements and logistics of CO2 offloading and its transport and utilisation and/or geological storage, providing practical recommendations for port authorities and industries. - WP3. Impact of SBCC on ship infrastructure

In this work package we investigate the integration of SBCC technology on board ships and its flexibility for large-scale use in multiple scenarios. The effect of ship motion on CO2 capture is a crucial one for SBCC’s development pathway. The technology brings additional challenges to both ship design and ship systems, such as deck space, added weight, impact on the LNG-vaporisation process and onboard heat management. These are key research questions being investigated in WP3, with our findings providing guidelines on retrofitting SBCC or integrating it into newbuild ships. - WP4. Environmental impact & techno-economic aspects

We will carry out a Life Cycle Assessment (LCA) within WP4. This considers the full chain of SBCC for both EverLoNG ships, including the fate of the captured CO2 once offloaded, transported, and geologically stored or utilised. The impact of greenhouse gas emissions alongside other impact categories, such as particulate matter formation or fossil depletion potential will also be investigated in the LCA.Mandatory energy efficiency measures – known as the EEDI/EEXI indices – are another approach for quantifying the emission reductions achieved by SBCC. WP4 and WP5 will use the findings of WP3 to investigate this.

As we know SBCC is economically viable, WP4 will explore all the techno-economic aspects of full-scale SBCC, including onboard capture, intermediate CO2 storage, and the cost of full CCUS chains. We will develop a methodology that will help determine an optimal strategy based on transit length and the availability of ports with a CO2-receiving infrastructure. This methodology will be used for Techno-Economc analysis (TEA) on full CCUS chains.

- WP5. Regulatory frameworks

WP5 brings together technology developers and three major class societies – namely, Bureau Veritas Norway AS, Lloyds Register and DNV – to ensure that the technology’s design is in line with current safety regulations. Integrating safety assessments and regulatory aspects from the early stages of design will ensure the success of SBCC implementation in the near future. In this way, ship owners and SBCC developers can address any potential issues during the early design stages and make SBCC risk free for future approvals. - WP6. Dissemination & knowledge sharing

Sharing information and results generated by EverLoNG is key to their uptake by stakeholders, which include the international shipping community, workforces, connected industries, policymakers, national and international governments with responsibility for climate targets, and the wider public. Members of WP6 have developed the EverLoNG visual identity to unite our international partners under one flag and boost recognition.

Promising results

The first demonstration campaign of CO2 capture in the EverLoNG project was planned to occur on the Sleipnir vessel of Heerema Marine Contractors. The mobile CO2 capture plant from TNO (microplant) has been used. Due to limitations caused by COVID-19, TNO’s engineers had limited access to the Sleipnir. Therefore, TNO and Heerema Marine Contractors agreed on and executed an alternative plan: the microplant was installed onboard of a barge, next to the Sleipnir vessel. Heerema Marine Contractors provided a gas line connecting a slip stream of the exhaust gas from one of the Sleipnir engines to the microplant. In this way, the campaign could still be carried out, with only minor consequences to the project.

“We know the performance of the CO2-capture technology on land, so these first results are really promising to implement this technology in the near future on board ships.”

A test campaign of 225 hours has been completed successfully. The campaign has shown that CO2 capture from a ship engine is feasible, and that even with low available packing height, relatively high capture rates can be achieved. In this campaign the capture rates are 60% to 70%: quite promising results so far.

The demonstration of ship-based carbon capture at the TotalEnergies’ LNG carrier and Heerema’s Sleipnir are currently planned for 2023 and 2024.

EverLoNG is a three-year international research initiative involving the maritime, R&D and engineering sectors and co-funded by the ERA-NET ACT3 programme, project number 327332. Financial contributions have been made by the Ministry of Economic Affairs and Climate Policy, the Netherlands; The Federal Ministry for Economic Affairs and Climate Action, Germany; the Research Council of Norway; the Department for Business, Energy & Industrial Strategy, UK; and the U.S. Department of Energy. All funders are gratefully acknowledged.

Read more about EverLoNG

Sebastiaan Rodenhuis fotografie

Sebastiaan Rodenhuis fotografie Conoship International

Conoship International