When naval architects envision future vessels, they can think up the best solutions. Driven by the increasing need for a more sustainable shipping sector, we have to research and develop zero-emission transport solutions. This is especially true for vulnerable areas such as the Wadden Sea, where a reduction in emissions instantly reduces damage to the environment.

Designing a high-speed methanol fueled ferry

Conoship International has a long track record with ferries, especially for the Dutch and German Wadden Sea. Based on this experience and the need for sustainable transport solutions for this area, the idea came about to research solutions for a carbon-neutral ‘green’ ferry, suitable for a low carbon economy. The outcome? It’s possible now!

Starting point feasibility study

A ferry poses many challenges in regard to passenger safety regulations. Zero-emission, or carbon-neutral, also poses a lot of challenges regarding safety. Even though we like a challenge, we decided to base our research on an existing, and thus technically feasible, vessel. So, we started our explorations, and eventually case study, with the high-speed Adler Rüm Hart we developed for the Wyker Dampfschiffs–Reederei in 2018.

The Adler Rüm Hart is a lightweight aluminum and very compact catamaran passenger ferry with room for 250 passengers, sailing up to 18 knots at 750 kW on the shallow waters of the Wadden Sea. The vessel is designed according to the strictest environmental standards, minimizing ecological impact. For example, non-biocide coating is applied and the design complies to Blauer Engel „Umweltfreundliches Schiffsdesign“ and „Umweltschonender Schiffsbetrieb“. The innovative hull of the catamaran was designed and optimized to reduce ship resistance, keeping fuel consumption to a minimum.

Fuel Considerations

When looking at alternative fuels, there are several options. After careful consideration of the options and their related limitations, we concluded that the most suitable ánd future-proof fuel in this case study, is bio-methanol. Its properties make it suitable for a low-carbon economy and for a ferry with a fixed route (bunkering). The logistics are easy to set up in the Wadden Sea and, compared to Hydrogen, it is readily available and usable.

With bio-methanol, emissions are largely reduced and, unlike LNG, it can reach CO2 neutrality when it’s from a biomass source or synthetically produced with renewable energy. Finally, bio-methanol is safe for the sea environment and marine life. However, methanol is a low-flashpoint fuel and therefore subject to additional safety regulations for low-flashpoint fuels and gases.

Supported by Class

The development of a ferry on bio-methanol is new, and so is the regulatory process. The best way to achieve a fully functional, safe, and regulatory compliant vessel, is to join forces with Class as early in the process as possible. In this case, Lloyds Register is working with Conoship towards an Approval in Principle for the design of this methanol powered ferry. Currently, the draft interim guidelines for the safety of ships using methyl/ethyl alcohol as fuel, as recently approved by the IMO, are the leading set of guidelines for the design of a methanol ship. Together with Lloyds, we create a design that fully complies with these guidelines, and use the lessons learned in our many other ‘green’ and zero-emission designs.

Initial Design Phase / Research

After establishing the applicable rules, it is time to research the implications for the design of the ship and apply them to the case study: designing a 250PAX Catamaran Ferry with Bio-methanol as its fuel. Within the case study, it is assumed that the ship will purely sail on bio-methanol, with a small amount of ignition improver. The main takeaway for the approach of this study is to limit the design impact of methanol as a fuel compared to diesel. Keeping the design as simple as possible could improve the potential acceptance and decrease the complexity of bio-methanol as a fuel.

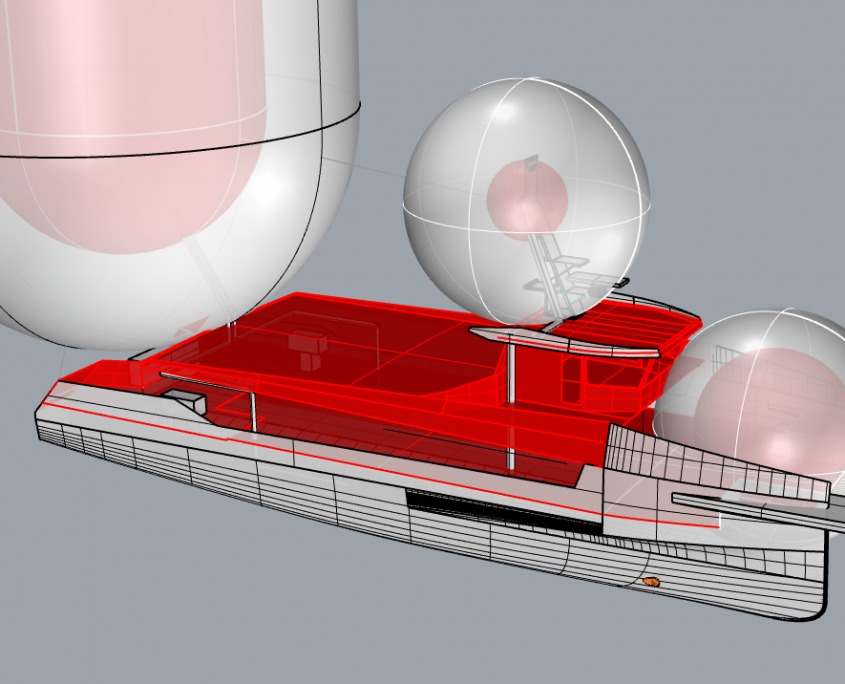

Risk assessment of hazardous zones on open deck with bio-methanol as a fuel. The inner spheres indicate a considerable chance that a flammable substance is ever present. The outer sphere indicates very exceptional chance. The aft mast is the outlet of the tanks and the foremast contains the inlets of them. The sphere on the foredeck is the bunkering station.

Lessons Learned

The overall conclusion of this case study shows that it could be possible to sail on bio-methanol when the right ventilation arrangements and protection of hazardous zones are fitted in the design. Based on the rules and the application of these rules, bio-methanol as a fuel does not have a significant effect on the general design of a ship. However, some systems need to be changed to achieve the goals and functional requirements of the rules. Especially in ventilation, structural fire integrity, and prevention of hazardous zones around passengers and machines more engineering work is required to achieve a design that fully complies with the rules. The keyword is ventilation.

Innovative Green Maritime Solutions

Since being founded in 1952, as the central design office for a group of Dutch shipyards, over 2,000 ships were built based on the designs of Conoship International. Many of which at the time of their launch were unique in the world, increasingly focusing on green shipping. This could be one of them.

Pictures courtesy of WDR, SIGU Design and Conoship International